Rock & Rubble

All manner of concrete, steel, and stone rubble from dredging, demolition projects, and other construction is used as artificial reef materials. This material is generally available at very low cost or free from construction companies who are more than happy to get rid of it. Transportation costs determine where this material is used by the Reef Program.

Using Concrete Rubble To Create Artificial Reef Habitat

Each year, millions of tons of concrete and steel debris are dumped into landfills in our state. This material is generated from the continuous demolition of aging buildings, bridges, roadways and piers. Now, the artificial reef program can use much of this material in a useful way to create marine fish habitat.

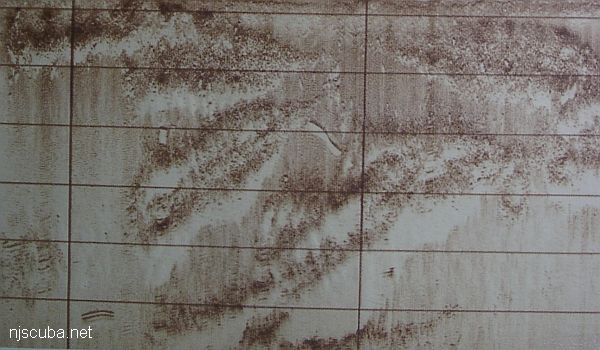

Chunks of concrete make ideal reef material. Concrete is dense enough so there is little problem with movement during storms and as it slowly ages it simply breaks down into sand and lime, two natural constituents of the ocean. A pile of concrete on the ocean bottom is a cheap imitation of a natural rock outcropping. providing a firm substrate for mussels and barnacles and all kinds of hiding places for sea bass. tog and lobster.

Acceptable demolition debris includes concrete, brick, stone, glass, and heavy gauge steel. Unacceptable are materials of low density, such as corrugated sheet metal, aluminum arid plaster. The debris must be free of floatables - wood, plastic, and containers. Fine particulate matter, which would include gravel, soil, and granulated concrete, cannot exceed five percent of the load by volume. As far as the fish are concerned, the bigger the pieces the better.

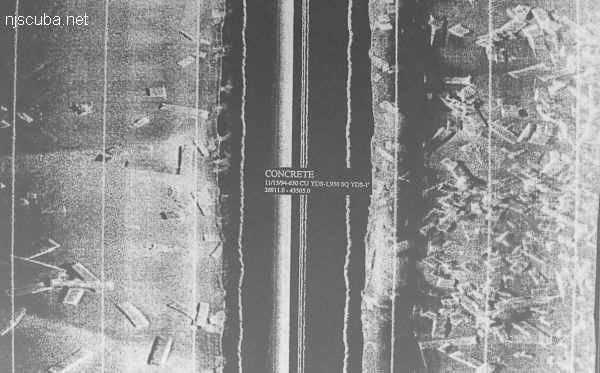

Rubble is transported to the reef site on large barges capable of carrying 3,000 to 5.000 tons of material. For slabs and boulder-sized chunks, deck barges are used; bulldozers push the material overboard. For smaller-sized chunks, less than a cubic yard. hopper or pocket barges which have a half-dozen or more hoppers, each with a trap-door bottom, are utilized. Once on the reef site, the doors are opened and piles of rubble drop straight to the ocean floor.

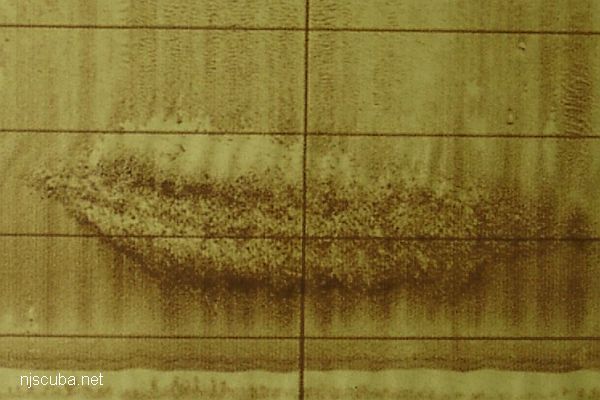

The strategy of making reefs with concrete rubble is to pile it up on top of itself. Because of its density, scattered pieces of concrete quickly subside and disappear into the sand bottom. Piling relies on the bottom layer providing a stable foundation and results in more structure jutting up above the bottom. To accomplish this, several barge loads of material are dropped at the same location.

From A Guide to Fishing & Diving New Jersey's Artificial Reefs

New Jersey Department of Environmental Protection, 1989

With concrete or other dense materials that tend to sink into the seafloor, the Reef Program tries to pile such structure on top of itself to ensure that some is left protruding from the sand. This is why they may focus drops from 10 or 20 barge-loads of concrete on one spot. Twenty years from now, concrete slabs will still project up from a foundation of other concrete that has since subsided into the sandy seafloor.

Granite has a density of 162 lb / cu ft, or 12.3 cu ft/ton. 1000 tons of granite is equal to approximately 450 cubic yards, or a solid cube 23 feet on a side.

Limestone has a density of 125 lb / cu ft, or 16 cu ft/ton. 1000 tons of limestone is equal to approximately 600 cubic yards, or a solid cube 25 feet on a side.