Boilers

Boilers are one of the most common shipwreck features, found on almost all engine-powered vessels. The purpose of a boiler is to produce high-pressure steam for the engine to propel the vessel. Steam boilers have been in use from the early 1800s to the present day.

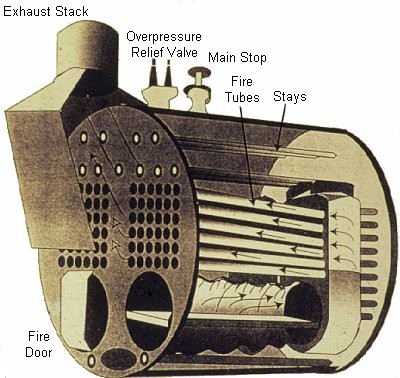

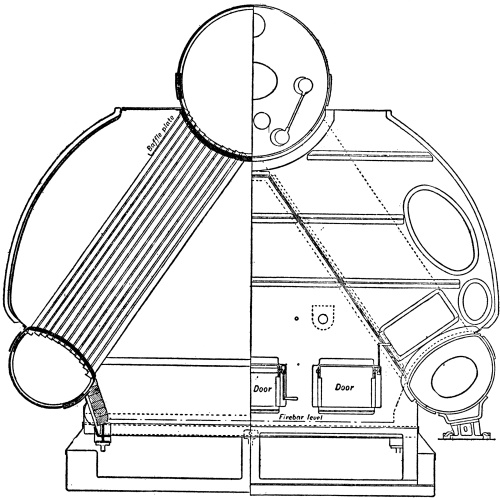

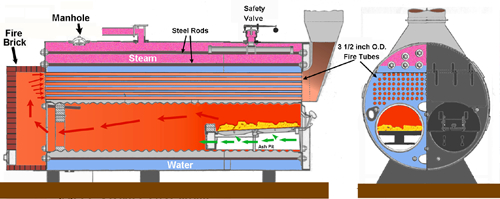

Most marine boilers fall into one of two types: fire-tube and water-tube. In a fire-tube boiler, the outer pressure vessel contains water, while the hot combustion gases are routed through small tubes - "fire-tubes" - inside, as illustrated above. This type of boiler had the advantage of being easier to control, but at the same time, the large volume of pressurized water and steam meant that a boiler failure would result in an enormous and usually catastrophic explosion. They are common in early marine applications and almost universal in locomotives.

Later, water tube boilers came into use. These used much smaller water reservoirs, interconnected with water tubes that were heated in the flue of the furnace. Usually, a final "superheating" stage is required to get steam at a usable temperature and pressure. Water tube boilers are more complex to operate, but also faster to "steam-up" when cold, and less prone to disastrous explosions. Smaller size and lighter weight makes them useful in mobile applications. Although they have completely replaced older technologies in marine use, water tube boilers were not successful in locomotives, and seldom tried.

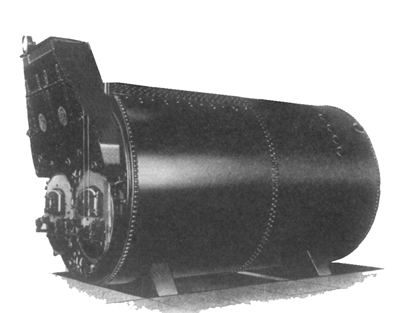

Because of the high pressures involved, boilers were constructed very strongly of iron and steel. Boilers are usually cylindrical in shape outside, with an array of small tubes and fins inside. Earlier vessels tend to have multiple small boilers, while later vessels will have just one or two large ones. Boilers could be fueled by either coal or, in later vessels, oil. The boiler is often the last part of a wreck to succumb to the destructive power of the sea.

Many later sailing ships, barges, and schooner barges also carried small boilers, although not for propulsion. Known as "donkey boilers", and usually mounted near the bow of the vessel, these were used to power steam winches and other equipment on the vessel, replacing manpower for tasks such as raising the anchor.

In a fire tube boiler, the hot gases from the combustion chamber are passed through tubes connecting perforated endplates. The gases then enter a "smoke chest" and pass on to a smokestack. This construction is typical of early maritime installations for boats and the boilers of steam locomotives. In a water tube boiler, the water is superheated in tubes exposed to the hot gases. A significant advantage of this type is that there is less chance of catastrophic failure, as there is not a great amount of water in the boiler, nor are there large mechanical elements subject to failure.

Boilers on nineteenth-century wrecks such as the Delaware tend to be collapsed or caved in, exposing the fire tubes and other interior components. Those on more recent wrecks such as the Mohawk are more likely to be intact, appearing as large and sometimes huge iron cylinders.

A condenser like this was used to cool waste steam from the engine using seawater. The purpose of this was two-fold: first to reclaim the freshwater for re-use in the boiler, and second, to draw a vacuum on the exhaust side of the engine, increasing its output. This condenser was recovered from the Cecilia Dunlap.