Engines

Steam Engines

Steam engines are a common sight on New Jersey shipwrecks. Usually the highest point of relief on the entire wreck, the engine makes a good orientation point and is often used as a tie-in as well. Old steam engines were quite sturdily constructed, and last a long time in the ocean, although because of their value they were salvaged when possible.

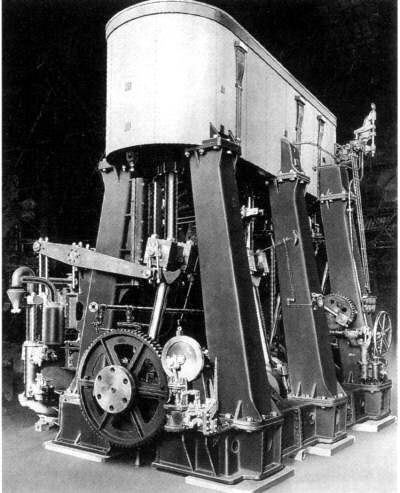

Right: The single-expansion steam engine of the Delaware, viewed over the top of one of the four boilers.

Steam for such an engine was generated in a boiler, where the fuel - wood, coal, or oil - was burned outside the engine. Hence the name external combustion engine, as opposed to the internal combustion engine ( in your car, ) where the fuel is actually burned inside the cylinders of the engine.

The earliest steam engines had just one large cylinder, as on the Delaware (1880), Brunette (1867), Emerald (1864 ), and many other older wrecks. In the 1870s, advancing technology produced more efficient two-cylinder compound or "double-expansion" engines, in which the steam exhausted from the high-pressure cylinder was re-used in the low-pressure cylinder. Towards the end of the nineteenth century, triple-expansion engines with three or more cylinders came into being. Finally, a few quadruple-expansion engines were built, but by then the reciprocating steam engine had been eclipsed by the turbine.

This engine is over twenty feet tall and produced 2500 horsepower at 76 rpm. The cylinders are 24, 37, and 70 inches in diameter. This was the last application of the reciprocating steam engine - already obsolete, but much less expensive to produce than turbines. It is a direct-drive system, with no transmission or gearbox. For reverse, the engine is stopped and then restarted in the opposite direction!

The cylinder head contains six individual cylinders, each individually cast and then bolted together into one unit. From left to right, these are: high-pressure inlet valve, high-pressure piston, intermediate-pressure inlet valve, intermediate-pressure piston, low-pressure piston, low-pressure inlet valve. All the pistons have the same stroke and are sized so that each produces the same power, even though each uses a different pressure and volume of steam.

Note how the low-pressure piston and valve are switched from their expected positions. This is actually very clever, as it gives constant spacing on the crankshaft, which simplifies manufacturing while at the same time resulting in a lighter and more compact engine.

Below each piston is a slider on a vertical track that mated the lower end of the piston shaft to the upper end of the crank rod. The piston shaft was fixed to the slider and moved vertically with the piston, while the crank rod was hinged to the slider and followed the rotation of the crankshaft. The crank rods and piston shafts are not installed, but the slider pivots are plainly evident. This design avoids placing sideways stresses on the cylinders, and is used in large diesel engines to this day. In the picture, all three sliders are at their lowest position, which they would never be at once if the engine were complete.

Below each connecting rod slider is a huge crank, with a bearing on either side. Below each valve is a set of eccentrics mounted on the crankshaft between the bearings. The notched flywheel was probably used to turn the engine over manually.

The thin supports on this side of the engine are removable, allowing the entire crankshaft to be removed in one piece. The heavy supports behind carry the connecting rod sliders and the mounts for the valve gearing, which is missing.

This engine was one of two from the ferry steamer City of Keansburg, which was built in 1926 and remained in service until 1968. In the foreground is the thrust bearing and the end of the ( starboard? ) propeller shaft. The pistons and top of the cylinder are missing. The engine is about twelve feet tall.

Typical triple-expansion steam engine installation, with auxiliary equipment. Propeller shaft at top; boilers would be forward.

Steam Turbines

Reciprocating steam engines remained in use through the 1940s until replaced by steam turbines and diesels. The Mohawk of 1926 and the Tolten of 1938, which appear to be lacking engines entirely, were actually powered by high-speed steam turbines.

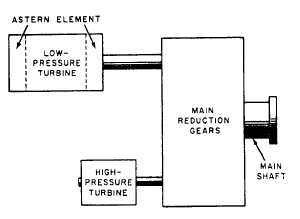

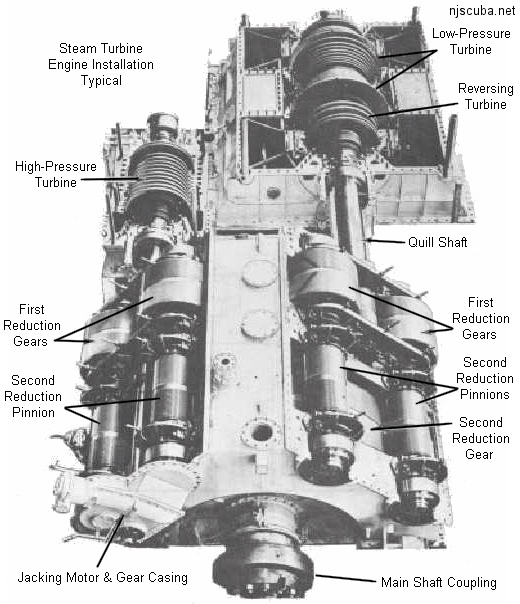

The high and low-pressure turbines are typically separate components, connected to the propeller shaft through a common reduction gearbox. The low-pressure turbine is powered by the exhaust from the high-pressure turbine. Reverse is provided by dedicated elements in the low-pressure turbine which turn the entire assemblage the other way; there is no reverse gear.

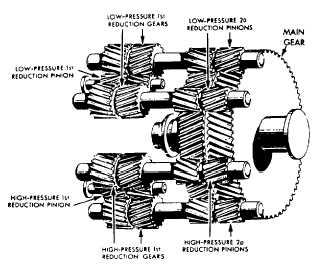

The first-reduction pinions are connected by flexible couplings to the turbines. Each of the first-reduction pinions drives two first-reduction gears. A second-reduction (slow speed) pinion is attached to each of the first-reduction gears by a quill shaft and flexible couplings. These four pinions drive the second-reduction gear that is attached to the propeller shaft. Two-stage reduction gears like this came into common use on ships after 1935, prior to that single-stage gears were more common.

The remains of the steam turbines are probably buried nearby. The rest of the gearbox appears to have rusted away.

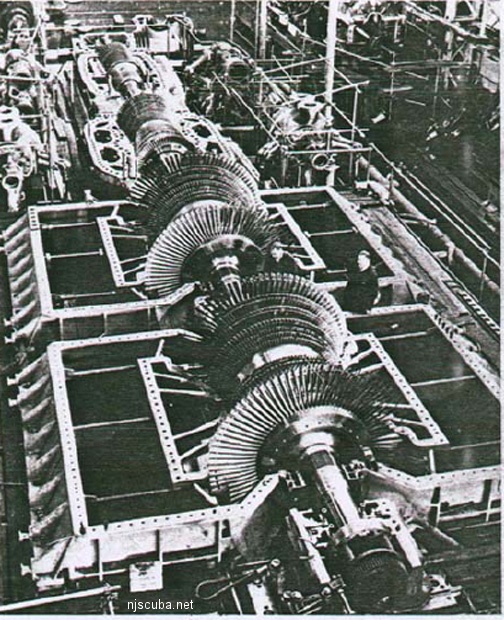

Low-pressure turbines are in the foreground, smaller high-pressure turbines are in the background. All are double-ended - steam is introduced in the center, and flows outward to both ends. In use, all the rotating components would be housed in massive steel casings. Some modern vessels even use gas turbine engines, similar in design and function to aircraft jet engines, and often derived from them.

I have never found the remains of a steam turbine on a wreck. These would be relatively small, low-lying pieces, constructed of high-strength steels that probably succumb quickly to the corrosive saltwater. Your best bet for seeing a steam turbine is probably the Algol.

Diesels

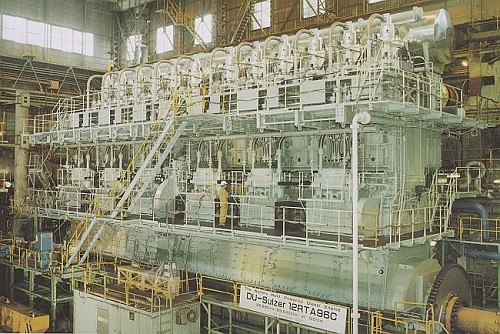

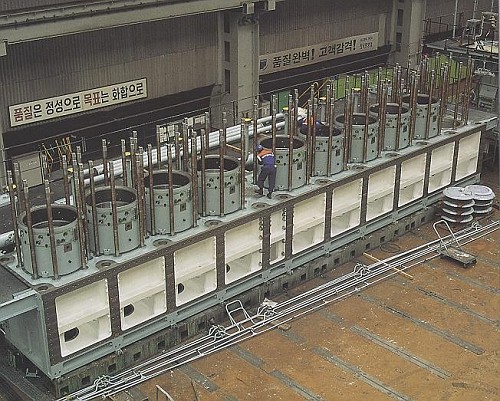

Many modern vessels are powered by diesel engines. One of the big advantages of diesel over steam is that it starts right up - no waiting for steam pressure to build. Diesel engines also do not require expensive high-speed gearboxes like turbines; large ones may be direct-drive, although smaller models may use automotive-like transmissions. A disadvantage of diesel power is the sheer size and height of the engine, which can easily fill the entire stern of the ship. For oil tankers, this is not a problem, but for vessels needing full-length internal decks, such as Ro-Ro ( roll-on roll-off ) freighters, this is unacceptable, and so lower-profile steam turbines are fitted instead.

At right is a typical tugboat diesel engine. A marine diesel engine like this might weigh several tons, but only put out 100 horsepower. That doesn't seem like much compared to your car, but you must consider that such an engine runs at very low RPMs, and puts out an incredible amount of torque. To see a good example of a marine diesel engine, visit the tugboat GA Venturo. These engines are reversed much like the steam turbines above - a change in valve timing and the engine runs backward!

The Pinta of 1959 was powered by a large diesel engine which is now exposed. The Stolt Dagali ( 1955 ) also has a big three-cylinder diesel, deep inside the wreck. You might be surprised to learn that most diesels, from the monsters shown here, down to the one in your favorite dive boat, are two-stroke engines, like a lawnmower. Four-stroke diesels are an automotive peculiarity.