Shipwrecks

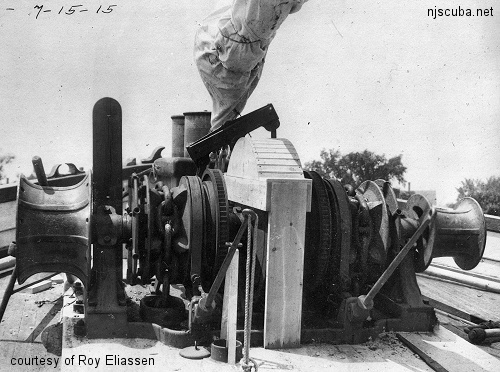

Prior to steam power, the only force available on a sailing ship to perform all the necessary work was the men on board. For some tasks, such as raising the anchor, it might be necessary to yoke the entire crew to a multi-deck manual capstan. On the largest vessels, even with every available man, this might take several hours to complete. With the advent of steam power, a "donkey engine" and a single engineer could do the work of many men, in less time, and these were soon installed in almost all vessels.

More: Capstans & Winches ...

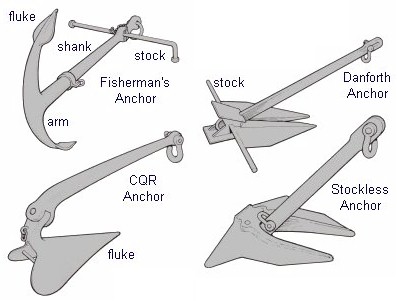

Anchors

Not all artifacts are easily recoverable. Ship's anchors often weigh in the hundreds or thousands of pounds and require a well-planned expedition to bring back to shore. At right is an assortment of anchors, from the old-fashioned "Fisherman's" anchor of the 1800s to the modern stockless or "naval" anchor, and its small cousin, the Danforth anchor.

More: Anchors & Chain ...

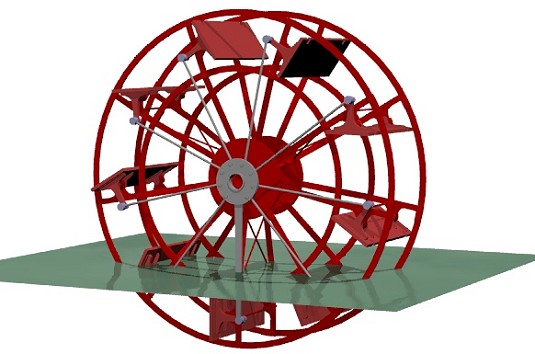

The paddlewheel predates even the steam engine. Horse-driven paddlewheel ferries have been in use for hundreds of years. Compared to screw-type propellers, the design and construction of a paddlewheel is much simpler, and therefore they remained the dominant method of propulsion through the mid-1800s, with some examples remaining in use until after World War II.

More: Paddlewheels ...

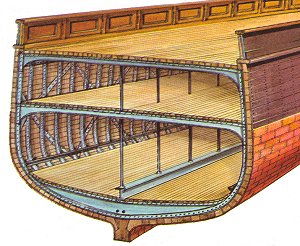

Iron and steel began to replace wood in ship construction in the middle to late 1800s. Timber-poor Europe ( especially England ) led in the development of iron ships, while America, with its vast reserves of lumber, continued to build wooden ships for some time longer. However, as the economical size of ships grew to surpass what could be built of wood, America too began constructing iron ships. For a few years, composite ships were built with iron frames and wooden skins, as seen at right, but difficulties with corrosion between the wood and metal soon led to hulls built completely of metal, both sailing ships and steamers.

More: Iron & Steel Ship Construction ...

More: Bits & Cleats ...

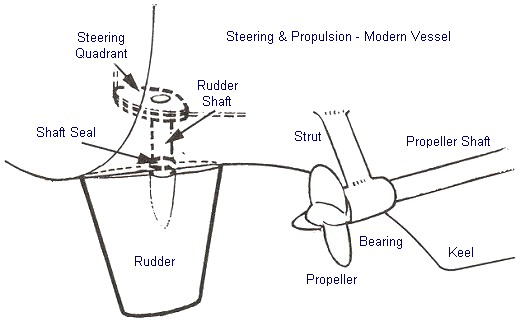

More: Propellers, Shafts & Rudders ...