Freighter (2/2)

Post-War Developments

After World War II, many pre-war freighters continued in use for many years. Thousands of Liberty and Victory ships carried cargoes around the world into the 1970s, mostly in third-world fleets. During this time there were a number of developments in cargo ship design. Not only did the vessels become much larger, they also became more specialized.

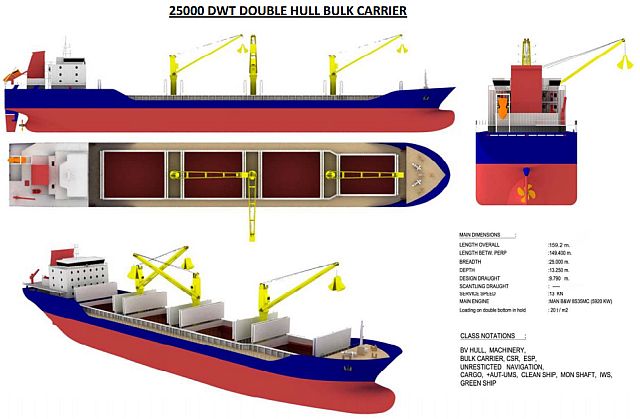

Bulk Carriers

Ships that move mountains, but also bring us our daily bread; dry bulkers are the workhorses of the maritime world. They are tough, unglamorous ships that mostly operate far from public gaze loading or discharging alongside huge piles of iron ore or coal or grain silos. Dry bulkers quite simply carry - in bulk rather than in bags of packages - any dry cargo that can be conveyed or grabbed, pumped, or blown into their capacious holds.

Bulkers come in every conceivable size, from the tiny single hold coasters wriggling over the mud in a North Sea creek, with a 500-ton load of animal feed or fertilizer to land at a rickety quay, to gigantic "Capesize" carriers of up to 230,000 tons, which spend their lives shuttling iron ore or coal in the deep sea trades between Brazilian mines and European steel mills or running the same raw material cargoes from Australia across the oceans to Japan.

Bulkers are incredibly efficient ships, and practically more than any other type of ship demonstrate staggering ton-mile figures. Because of their efficiency, there are power stations able to buy coal from Australia or Brazil, and have it delivered from the other side of the earth so that it is cheaper per ton than coal mined 20 miles from that power station. It just is a measure of what bulkers can do and why they are so essential to industry and any form of commercial enterprise.

Large bulk carriers will typically carry their cargo in nine holds, filled right up in the case of coal, but with lots of empty space if heavy, dense cargo like iron ore is aboard. They will have their machinery and accommodation right at the stern and they will depend on the shore loading equipment to fill them up, and shore grabbing cranes or other specialized equipment to discharge. Bulldozers will be lowered into the holds to move the cargo under the grabs, which in some ports can carry fifty tons in a single "bite".

More sophisticated ships will have their own cargo handling equipment, either derricks or cranes or conveyor systems able to land cargo 300 feet or more from the ship's side. There are more specialized vessels in the bulk ship family, such as cement carriers which push their cargo around through pneumatic systems, or "chip" carriers which handle the woodchip products of sawmills, which otherwise would be waste, but are transported around the world to become fiberboard and other valuable wood-based materials.

Bulk cargoes might seem to be uncomplicated, but the successful operation of bulk carriers still demands skill and expertise. Many bulk cargoes have hazardous properties, such as coal which is prone to spontaneous combustion, or iron ore concentrates which can have dangerous amounts of water in them. Free running cargoes like grain or cement are very prone to shift in heavy weather, which could menace the safety of the ship herself. Very heavy cargoes have to be loaded and discharged in a certain sequence, lest the structure of the ship be seriously stressed, while even large, deep-laden bulkers require careful handling in heavy weather, lest green water get aboard and stove in hatch covers.

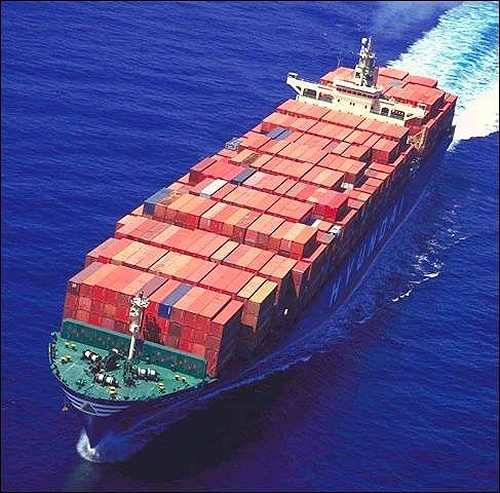

Container Ships

Containerization was an important element of the logistics revolution that changed freight handling in the 20th century. Malcolm McLean invented the shipping container in the 1930s in New Jersey and later founded Sea-Land corporation. It is said that while sitting at a dock waiting for cargo he trucked in to be reloaded onto a ship, McLean realized that rather than loading and unloading the truck, the truck itself, with some minor modifications, could be the container that is transported. The first container ships were converted tankers, built up from surplus tanker Liberty ships after World War II. Containerization revolutionized cargo shipping. Today, approximately 90% of cargo moves by containers stacked on transport ships.

Containerships were technology's answer to the problem of long stays in port as cargo - packed in bales, barrels, crates, boxes, and loose, was slowly loaded and unloaded in lower holds and 'tween-decks using gangs of dozens of dockers. It was not uncommon for a typical 15,000-ton cargo liner to spend 170 days each year in port and a ship in the Australasian trades could spend two months on the coast, after a month's voyage from Europe. This was inefficiency which encouraged innovation.

The container revolution effectively abolished all the expensive and time-consuming handling that was done to goods, in and out of lorries, trains, and warehouses. Loaded into a 20 ft. or 40 ft. container at the point of origin and sealed, the goods will not be seen again until they are delivered to their final destination. To handle the containers and speed them on their way, a whole logistic system has been developed from specialist road and rail transport, ground handling equipment, like straddle carriers and huge gantry cranes in the port terminals. And of course, the remarkable ships themselves.

Containers are the most obvious elements of international shipping; they are seen everywhere; trundling along the highway, in the factory loading bay, and stacked on rail cars. Containers were the units that became the common factor in a revolution that spread across the world of cargo liner shipping in the 1960s and 1970s and totally changed the face of the maritime industry.

The biggest deep-sea ships today are able to carry nearly a staggering 7,000 twenty-foot equivalent units ( the TEU being a universal measurement of containerization ), slotted into racks in the holds of the ship and stacked up to five high on deck. The ships themselves are fast, 25 knots not being unusual, but most importantly, they are far more precise and hugely more productive than their conventional predecessors. They will typically sail on a set hour on the same day of a week, often meeting trains that will on-carry the containers, so that consignees miles inland will be able to depend upon same-day delivery in a way that has never been possible before. This reliability makes it possible for manufacturers or retailers to greatly reduce the amount of stocks they are forced to carry, which saves substantial sums. Most container ships are propelled by diesel engines and have crews of between 20 and 40 people. They generally have a large accommodation block at the stern, directly above the engine room.

Large container ships tend to minimize their port calls, restricting them to "hub" ports along their route, the containers being distributed to other regional ports by smaller feeder ships. A single shore gantry crane can handle from 20-30 lifts per hour, so port calls are generally measured in hours rather than days. Container shipping is a high technology, capital intensive operation, with heavy reliance on IT; computers being used to plan the stowage, to minimize handling of containers. The most modern container terminals now use a high degree of automation for the movement of boxes from the shore container stack to the ship's side. Recent years have seen containership sizes react to scale economies, with the "1st generation" ships of 1,200 TEU having now grown to an average in excess of 5,000 TEU on the deep-sea trades. Giants of 10,000 TEU plus are now being planned.

RO/RO ( Roll-On / Roll-Off ) Ships

A Roll-On/Roll-Off [RO/RO] ship is specifically designed to carry wheeled and tracked vehicles as all or most of its cargo. A series of external and internal ramps facilitate the loading and discharge of RO/RO cargo. Vehicles are driven or towed on and off the ship by means of either the ship's own ramps or shore-based ramps. Because it is designed to accommodate cargoes that cannot be stacked but which vary in height, below-deck space and volume utilization is generally less efficient than on a containership. RO/RO ships are thus commercially viable only in certain specialized trades.

RO/RO ships have been around for a very long time, although the first wheeled vehicles to be rolled, instead of lifted, onto ships were rail wagons with the first rail ferries appearing at the end of the 19th century. It was the 1950s when the first commercial ro-ro ships appeared in the ferry trades, initially derivations from the WWII landing craft, with cargo being loaded over a bow ramp, lowered onto a beach or simple jetty structure.

These very basic ships demonstrated one very important thing - that it was much faster to roll vehicles on board than it was to lift them. The big breakthrough came when classification societies and regulators agreed that it was safe and feasible to cut an opening in the stern of a ship, sufficiently large to roll vehicles through it, and to design ships with long, flat decks, rather than to subdivide the vessel by athwartships bulkheads.

While the main thrust of RO/RO remained in the ferry and short sea freight trades, by the 1970s, the principle was being taken into the deep sea trades, large RO/RO vessels often carrying a mix of containers and wheeled cargo. Their ability to carry heavy and awkward cargo was greatly prized. Specialist car carriers arrived and before long there were twelve-decked ships of this type that could load more than 5,000 standard-sized cars.

Cargo handling technology has been at the root of the RO/RO ship's success. Watertight doors, amazing angle ramps that enable a ship to operate without shore link-spans at any stage of the tide, hydraulic internal ramps, and huge elevators for movement between decks are just some of the equipment that is seen on modern ro-ro vessels. Portable car decks which can be tucked up under the deck above when not required give a ferry a flexible capability that can cope with seasonal demands for cars or freight vehicle space.

Like most other types of ship, RO/ROs have got bigger, faster, and more sophisticated. A drive-through RO/RO of perhaps 30,000 tons is able to discharge 350 cars, 100 trucks, and more than one thousand passengers and load the same number in little more than an hour. There are now 60,000-ton ferries on the North and Irish Sea, while there are overnight ferries in the Baltic, which combine the characteristics of luxury hotel, shopping mall, and entertainment complex. Moreover, there are big freight ferries that can take up to 4 miles of trucks - which makes environmental sense.

RO/RO is also the preferred ship type for the deployment of military equipment. The military advantages of RO/RO ships include the capability for rapid loading and discharge of vehicles and non-self-deployable aircraft, and open deck areas well-suited to the carriage of outsized military cargo or standard containers. Eight such RO/RO ships can transport an entire Army mechanized division at a speed of 30 knots, which has made them extremely useful in the recent Mideast conflicts. The Marine Corps uses several such vessels to pre-deploy equipment to distant locations. Extensive ship-board environmental systems maintain suitable long-term storage conditions. Container ships are also used for prepositioning.

Automobile Carriers

The automobile carrier is a specialized type of RO/RO ship. They are clearly not the most beautiful of ships, but modern car carriers are extraordinary, specialist ships that carry out their functions with considerable efficiency. They are ships that have evolved to address a specific need, namely that of the international car industry which requires to ship tens of thousands of cars around the world between their factories and their markets.

They have developed in response to what has become a global industry, with car plants distributed around the world, global sourcing of components, and more recently a system of locating different model production in different countries. The ships, therefore have become an integral part of the process of car production and distribution and the industry, quite simply, could not work without them.

Cars were once shipped around the world in the 'tween-decks of general cargo carriers, on portable decks slotted into the holds of bulk carriers, or even in refrigerated ships (reefers) which, with their reefer plant turned off, could usefully carry quite large numbers ion their multiple decks. But all these ships had to lift the cars on and off, which was inefficient and risked damage if the crane driver was less than expert or the dockers insufficiently vigilant. So the notion of driving cars on and off in a specialized version of a roll-on, the roll-off ship was born and quickly reached fruition.

Car carriers are, quite simply, floating car-parks; large multi-decked vessels with cars packed in, nose to tail, in up to twelve decks just higher than the average sedan car. The largest deep-sea car carriers carry up to 6500 standard sedans. The ships tower out of the water, cars being relatively light compared with their volume, and have to be loaded and unloaded in a special sequence, almost like a puzzle, that ends and begins with the "key car", with every last parking space being occupied.

The ships are easily identified by their size and silhouette, and usually have a ramp at the stern, and another on the same side about amidships. With all those car engines working, when the ship is handling cargo, and with petrol in the tanks, huge ventilation requirements are provided for, but the ships tend to be relatively uncomplicated and practical vessels, with most offering a couple of strengthened and higher decks for lorries or other high sided vehicles. While the deep-sea trades see these monsters, they tend to work to "hub" ports, from where smaller feeder ships distribute the cars to their ultimate port destinations. These are also specialist vessels, but handier and more like ferries.

Car carrier operators have long-term contracts with vehicle manufacturers and cleverly plan their schedules to ensure that the ships have very few voyage legs when they are running empty. In this, they are helped by the manufacturers, who have considerably consolidated and moved their factories around the world so that, for instance, Honda cars are carried from Japan to the US, and surprisingly, different model Hondas exported from the US back to the Far East.

Refrigerated Ships

In the year 1880, there was an important breakthrough when 400 frozen carcasses were carried safely by sea using a simple ship refrigeration plant to keep them hard-frozen on a two-month voyage from Australia to the United Kingdom. This had huge implications, both for the consumers, who were able to source their produce from across the world and to the producer countries like Australia and New Zealand, which were permitted by seagoing refrigeration to develop their main export markets.

Since these beginnings, the "reefer" trades have hugely expanded to handle all forms of fresh food, with substantial quantities of meat, fish, dairy produce, bananas, citrus, and other fruits crisscrossing the world in specialized refrigerated ships. Cargoes are carried either frozen, chilled, cooled, or increasingly at controlled temperatures that can be varied to ensure that the produce reaches the market at its optimum condition, often ripening on the voyage.

Reefer ships are effectively large refrigerators, heavily insulated with modern glass fiber or similarly efficient insulation, shuttered with bright metal that prevents taint and is easy to clean. They are ships that tend to be divided into many more spaces than conventional dry cargo ships, with several 'tween-decks and even locker spaces, so that different commodities can be separated and carried, if required, at different temperatures. Below decks, a reefer ship resembles a large modern warehouse, and cargo is usually carried and handled in palletized form, moved about on conveyors or by electric forklift trucks. Some cargo, such as bananas, is often handled through doors in the ship's side. Cleanliness and the maintenance of optimum temperatures are the prerequisites.

Modern refrigeration plant works with environmentally kind refrigerants such as R-22 and is largely automated. Air is cooled in a brine cooling system by screw compressors and cold air ducted to the cargo spaces. Reefer ships have sometimes been employed to carry cars, as their multiple decks are suitable, but this is less usual with the growth in the number of specialist car carriers. They can usually, however, carry refrigerated containers on deck. A large reefer ship might typically offer about 500,000 cubic feet of refrigerated space, and be capable of loading 250 containers on deck.

Reefers operate seasonally, but because there is a heavy trade between the hemispheres, can hopefully find employment. In recent years, too much new construction has led to a situation of over-tonnage. The specialist reefer ships, which are generally operated as tramps rather than in the liner trades are seeing their cargo base increasingly attacked by large container ships, which are offering more slots for refrigerated boxes. Indeed the largest reefer capacity in a single ship is now found, not on a "traditional" reefer, but aboard a large container ship.

Reefer containers are either fitted with their individual refrigeration units which can be plugged into the ship's electrical power source, or, less usually, with apertures for ducted cold air. With the increase in exotic food cargoes, special containers have been devised that can tailor the internal atmosphere to the precise requirement of the foodstuffs.

LASH - Barge Carriers

Every moment that a ship is in port, she is not earning, so enormous efforts have gone into devising means of minimizing port calls and improving the handling of cargo. The barge carrier was designed for this precise reason. The principle of the barge carrier is simple; a "mother ship" that arrives in port, drops off a number of large barges and loads some more, then moves off to the next port, leaving the barge units to be discharged and then loaded at leisure. Moreover, on routes such as between two great rivers, such as the Mississippi and Rhine, it would be necessary only for the mother ship to call at the mouths of the two rivers, leaving tugs to tow the barges to a whole range of river ports. And most important, barges would be sizable units of up to 400 tons, so that all types of cargo could be carried.

The first barge carriers were designed in the late 1960s and were impressive ships. Known as "Lighter Aboard SHip" or LASH carriers, these were long fast cargo liners of massive construction, with the bridge forward, and a massive gantry crane mounted on rails on deck. The crane is able to lift a laden barge of up to 440 tons out of the hold, roll it right down aft and launch it over the stern. No fewer than 80 watertight stackable barges could be carried in and above the five holds of the huge, 50,000-ton ships. During the 1970s there were 22 large LASH ships built, and they have been successful in trades that did not justify the use of containers, such as semi-bulk cargo like paper or pulp, steel products, and other forest products. United States owners were particularly keen on this design, and it is significant that their huge carrying capacity and enormous gantry crane has made them useful as auxiliaries for the US armed forces.

While the 400-ton barge was a spectacular size of unit, it still was not judged adequate and three other giant barge carriers, known as Seabees were built in the 70s. These were truly astonishing ships that were fitted with a massive stern elevator that could lift two laden 850-ton barges simultaneously out of the water to the required deck level, and then roll them forward into their stowage position. Each Seabee carried 38 barges and operated across the North Atlantic for about 10 years. Then their US owners decided to invest in container ships but fortuitously sold the three Seabees to the US Government, which had ascertained that just one of these huge ships was capable of carrying a complete armored division. They have remained as military auxiliaries ever since. At the same time, the Russians were designing a nuclear-powered icebreaking barge carrier on the same principles as the Seabee, for service in the Soviet Pacific coastal trades.

LASH vessels require little in port facilities, as the individual barges are fairly small ( 30 x 60 ft ) and easily handled by local tugs. The individual barges are considered to be vessels in their own right. Barge carriers are "niche" ships that have only been built in restricted numbers. A new generation of replacement tonnage, however, is currently being planned.

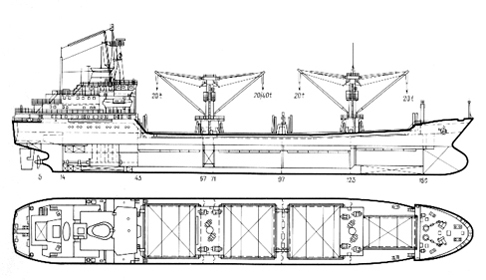

General Cargo Ships

Yes, the old-fashioned general cargo ship still exists as well, because some things just don't fit in a forty-foot box!

Despite being firmly in the container age, with a vast number of commodities being carried in those ubiquitous boxes, not every cargo can be handled in such a fashion. "General" cargo constitutes that myriad of goods that are not liquid or bulk or containerizable, and there is still a sizable fleet of ships that will carry such cargo.

A general cargo ship is designed to carry pretty well every form of dry cargo that is on offer. Long iron such as railway lines or constructional steel is a natural for this type of ship, while rolling stock, agricultural machinery and a whole range of factory plant will need a capable sort of ship to accommodate these large, awkward loads. Steel coils are heavy, difficult cargoes that need special stowage, while the "big bags" containing dry chemicals and small consignments of bulk are ideally suited to the modern general cargo ship.

An older type of general cargo ship is the "'tween-decker", which is a survivor of pre-container days when all dry general cargo was handled in such vessels on both the liner and tramp trades. The 'tween-decker has more than one deck above its lower hold, the cargo space may be divided into up to six holds so there are a large number of separate compartments in which cargo may be segregated.

General cargo ships will invariably have their own cargo gear, either cranes or derricks, to enable them to trade into ports where there is little port equipment. They may even have a heavy lift derrick to enable large loads of typically up to 70-80 tons to be handled, independently of any shore cranes. Self-sufficiency is the watchword on the general cargo ship.

More modern general cargo carriers tend to have fewer holds, so that larger and bulkier loads can be handled, and hatches that are almost as wide as the ship herself, to enable the cargo to be "spotted" without having to be dragged in and out of the wings, as was the case with old 'tween-deckers, where the hatches were smaller. They also tend to have cranes that are able to work in tandem, thus doubling the weight that can be carried. Such facilities are very useful for project cargo, where a whole factory or large parts of a chemical plant might be carried on a single ship and delivered close to the destination. And if general cargo is not available, these ships can usually find employment carrying a load of containers or a consignment of bulk cargo or bag work.

Those who sail in general cargo ships speak of the variety of the work, and of the longer spells in port when cargo has to be carefully stowed so that there is no lost space, cargo cannot move and the stability of the ship at all stages of the voyage needs to be allowed for. There is quite an art to stowing a general cargo ship for a number of port calls, ensuring that every item of cargo is identified and that its stowage is detailed, so that it neither becomes "over-stowed" by cargo that is to be discharged at a later port, nor is squashed by heavier cargo. The optimum carriage conditions for a whole range of different goods that may deteriorate on voyage must also be provided. Those running large fast container ships may look down their noses at the humble general cargo ships they meet at sea. But these vessels are vital for world trade, and if they were not available many of the world's goods would not find their way to market.

Heavy-Lift Ships

The USS Cole was transported back to the US on a semi-submersible heavy-lift ship after she was attacked and disabled by terrorists in Yemen.

Heavy-lift ships are built to carry outsized items. Anything from fully-assembled oil platforms to other ships may be loaded onto the back of one of these floating flatbeds. They are probably the rarest of cargo vessels, and very unlikely to be seen around here.

text largely adapted from Wikipedia and Bimco

many photos courtesy freefoto.com