Artificial Reefs Materials

Why Do We Build Reefs the Way We Do?

Over the years, our reef-building tactics have been challenged by fishermen through comments like: don't put that concrete on top of good structure; don't spread out tire units, pile them up, it's easier to fish on; why don't you sink some ships on the Sandy Hook Reef? Believe it or not, there are well-thought-out strategies behind our reef-building efforts. Let's examine some of them.

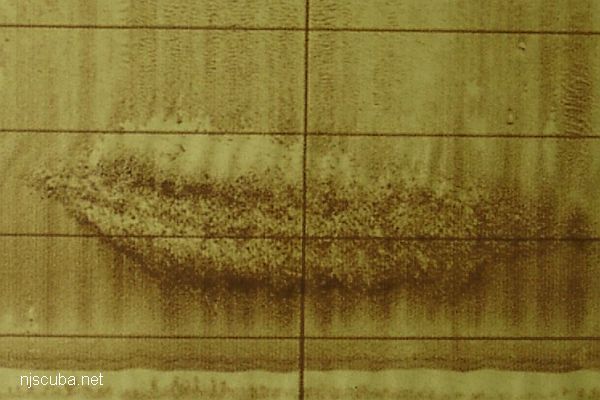

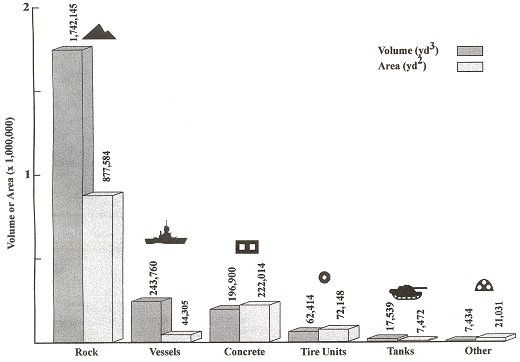

Overall, our reef network is designed to maximize the benefits of the materials that are available to us for reef construction. The primary criteria that determine what materials are placed on a reef are depth and distance from the ports of New York or Philadelphia. Reef site depth dictates the height of the structure that can be sunk there. For example, we cannot sink a large ship with a 50-foot high superstructure on the Sea Girt Reef, which is only 70 ft deep, but must move offshore to the Shark River Reef where depths are sufficient, over 125 ft. Large concrete demolition projects originate in the ports of New York and Philadelphia. Distance to a reef site is the major factor in determining if reef deployment is a cost-effective alternative for contractors. Consequently, Sandy Hook and Cape May reefs, the closest sites to major ports, have received most of the demolition debris used to build reefs. Sandy Hook Reef receives so much rock and concrete that it is unnecessary to sink other structures there when they are needed more for mid-coast reefs.

Recognizing that reefs in the mid-section of the state are outside of the range of demolition contractors, we have targeted these sites for concrete-ballasted tire units, army tanks, and small vessels. With many reef deployments dependent upon limited funds available from donations, we have attempted to divide materials among reef sites as equitably as possible.

With concrete or other dense materials that tend to sink into the seafloor, we try to pile such structure on top of itself to ensure that some is left protruding from the sand. This is why we may focus drops from 10 or 20 barge loads of concrete on one spot. Twenty years from now, concrete slabs will still project up from a foundation of other concrete that has since subsided into the sandy seafloor.

In contrast, less dense materials, such as concrete-ballasted tire units that tend to rest on the surface of the ocean bottom, are spread out across the seafloor. Since the quantity of marine life is dependent upon the amount of surface area of the structure, dispersed tire units will have more surface area and consequently, a greater population of fish than the same number of units placed in a pile. Spacing helps both fish and fishermen. A party boat anchored on a tire unit pile can catch many of the fish there in one or two trips. Spread-out units will sustain greater fishing effort and provide good catches over a longer period of time.

A successful strategy has been to design reef sites with separate anchor and drift areas. The former area consisting of vessels or tanks; the latter of spread-out tire units. This feature reduces conflicts between anglers and divers and allows large numbers of inexperienced wreck fishermen to use drift areas where finding and anchoring on specific structures is unnecessary.

A new strategy that we hope to soon implement is the deployment of widely-spaced refuge / juvenile habitats. Such structures will be small, fabricated out of concrete, and designed to benefit juvenile fish and shellfish. They will be randomly distributed at a low density of only 1 or 2 habitats per acre of seafloor, too spread out for use by anglers or divers. Their objective, however, will be to produce fish for future harvest.

These articles first appeared in New Jersey Reef News - 2000-2003