Wood & Organic Materials

All woods turn black after prolonged immersion.

Botanically, wood is the xylem tissue that forms the bulk of the stem of a woody plant. Xylem conducts sap upward from the roots to the leaves, stores food in the form of complex carbohydrates, and provides support; it is made up of various types of cells specialized for each of these purposes. Among them are tracheids, elongated conduction and support cells; parenchyma ( food storage ) cells, some of which form rays for transverse conduction; xylem vessels, formed of hollow cells joined end to end; and fiber cells that reinforce these tubes. In the conifers the xylem is made up mainly of tracheids, thus presenting a uniform, nonporous appearance; their wood is called softwood. Deciduous trees have more complex xylem, permeated by vessels, and are called hardwoods, although the description is sometimes inaccurate.

The xylem is formed in the growing season by the cambium; in temperate regions, the cells formed in the spring are larger in diameter than those formed in the summer, and this results in the annual rings observable in cross-section. The new cells lose their protoplasm as they form the various tissues; the older, nonfunctional cells become plugged up, darken in color, and often accumulate bitter or poisonous substances ( tannins, dyes, resins, and gums. ) This inner wood ( the heartwood, as opposed to the functional sapwood ) is valued for outdoor construction because of its resistance to moisture and to decay-producing organisms.

Commercial Uses

Freshly cut wood contains much moisture and tends to warp and split as it dries. Lumber is therefore seasoned before use - dried either slowly in the sun and air or more quickly by artificial means ( kiln drying. ) Seasoning increases wood's buoyancy, strength, elasticity, and durability. Although synthetic materials have supplanted wood in many of its former uses, it is still widely employed for furniture, floors, railway ties, paper manufacture, and innumerable other purposes. Wood distillation yields methyl alcohol, wood tar, acetic acid, acetone, and turpentine; charcoal is made by burning wood in insufficient air to consume it.

The wood of different species of trees varies considerably in weight, strength, and appearance. Softwood is normally uniform in grain ( texture ) and color; hardwood, in which the rays are more prominent and the arrangement of tissues is variable, produces lumber in which the grain may run vertically or horizontally and be coarse or smooth. The manner in which a log is cut results in lumber with thin or wide ray markings. A log cut horizontally shows the concentric annual rings; lengthwise cuts through the center are marked by thin vertical ray lines; and lengthwise cuts through the outer sections show the wood's characteristic wavy grain and wider ray markings, prized for their beauty. The rarer decorative woods may be cut in thin layers and glued to other wood structures.

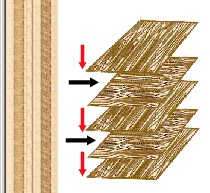

Plywood, made of thin layers of wood glued so that the grains alternate in direction, makes an especially strong construction material. For some applications, composition board offers another inexpensive substitute.

Lignum vitae - an extremely dense, tough, hard, oily tropical wood that was much used in shipbuilding before the advent of high-strength metals. Lignum vitae, along with elm, was used for articles requiring great strength and hardness, such as bushings, bearings, pulleys, blocks, and deadeyes.

Leather

Leather is the skin or hides of animals, cured by tanning to prevent decay and to impart flexibility and toughness. Prehistoric and primitive peoples preserved pelts with grease and smoke and used them chiefly for shoes, garments, coverings, tents, and containers. Today pelts are prepared for tanning by de-hairing, usually with lime, followed by fleshing and cleaning. After tanning, leather is generally treated with fats to assure pliability. The practice of shaving leather to the required thickness was abandoned early in the 18th century after the invention of a machine that split the tanned leather into a flesh layer and a grain ( hair-side ) layer; skivers are thin, soft grains used for linings and for covering firm surfaces.

Characteristic grains may be brought out by rubbing, as in morocco leather ( goatskin ) or may be imitated by embossing. Finishes include glazing, a high glaze being achieved by rolling with glass cylinders; coloring with stains or dyes; enameling or lacquering as for patent leather; and sueding, buffing with emery or carborundum wheels to raise a nap, usually on the flesh side. Russia leather, originally vegetable-tanned calfskin dressed with birch oil that imparted a characteristic odor and often dyed red with brazilwood, is a term now covering a number of variants. Rawhide is similar to parchment and is untanned. Cordovan, or Spanish, leather, a soft, colored leather made at Cordoba during the Middle Ages and often richly modeled and gilded, is imitated for wall coverings, panels, and screens. Leather is much used in bookbinding.

Artificial leather, made since about 1850, was originally a strong fabric coated with a rubber composition or with a synthetic substance such as pyroxylin. Since World War II, materials made from vinyl polymers have far outstripped the earlier artificial leathers in commercial importance.

Tanning is the process by which skins and hides are converted into leather. Vegetable tanning, a method requiring more than a month even with modern machinery and tanning liquors, employs tannin; its use is shown in Egyptian tomb paintings dating from 3000 B.C. Mineral tanning includes tawing, or alum tanning, another ancient method, and chrome tanning, the process most common today, based on the use of chrome salts and requiring only a few hours. Known as early as 1856, chrome tanning was first patented in the United States by Augustus Schultz in 1884. In oil tanning, or chamoising, the pelts are treated with fats and hung to dry; the leather is commonly napped on both sides and is very absorbent.

The most recently developed tanning process employs artificial agents (syntans.) Most heavy leathers, such as sole leather, are vegetable-tanned; many light leathers are chrome-tanned. The Native Americans of North America used the chamois method, employing the fat, livers, and brains of animals. Their tanned white buckskin was highly esteemed, especially for clothing, both by Native Americans and by colonial pioneers. In the tanyards of European settlers tanners used oak and hemlock bark; gallnuts; the wood, nuts, and leaves of the chestnut tree; and the leaves of sumac.

Textiles

All fabrics are made by weaving, felting, knitting, braiding, or netting, from the various textile fibers.

Textiles are classified according to their component fibers into silk, wool, linen, cotton, such synthetic fibers as rayon, nylon, and polyesters, and some inorganic fibers, such as cloth of gold, glass fiber, and asbestos cloth. They are also classified as to their structure or weave, according to the manner in which warp and weft cross each other in the loom. Value or quality in textiles depends on several factors, such as the quality of the raw material used and the character of the yarn spun from the fibers, whether clean, smooth, fine, or coarse, and whether hard, soft, or medium twisted. Density of weave and finishing processes are also important elements in determining the quality of fabrics.

Tapestry, sometimes classed as embroidery, is a modified form of plain cloth weaving. The weaving of carpet and rugs is a special branch of the textile industry. Other specially prepared fabrics not woven are felt and bark ( or tapa ) cloth, which are beaten or matted together, and a few in which a single thread is looped or plaited, as in crochet and netting work and various laces. Most textiles are now produced in factories, with highly specialized power looms, but many of the finest velvets, brocades, and table linens are still made by hand.

Yarn, fabrics, and tools for spinning and weaving have been found among the earliest relics of human habitations. Linen fabrics dating from 5000 B.C. have been discovered in Egypt. Woolen textiles from the early Bronze Age in Scandinavia and Switzerland have also been found. Cotton has been spun and woven in India since 3000 B.C., and silk has been woven in China since at least 1000 B.C. About the 4th cent. A.D., Constantinople began to weave the raw silk imported from China. A century later silk culture spread to the Western countries, and textile making developed rapidly. By the 14th cent. splendid fabrics were being woven on the handlooms of the Mediterranean countries in practically all the basic structures known to modern artisans, and there has been no change in fundamental processes since that time, although methods and equipment have been radically altered.

compiled from various sources